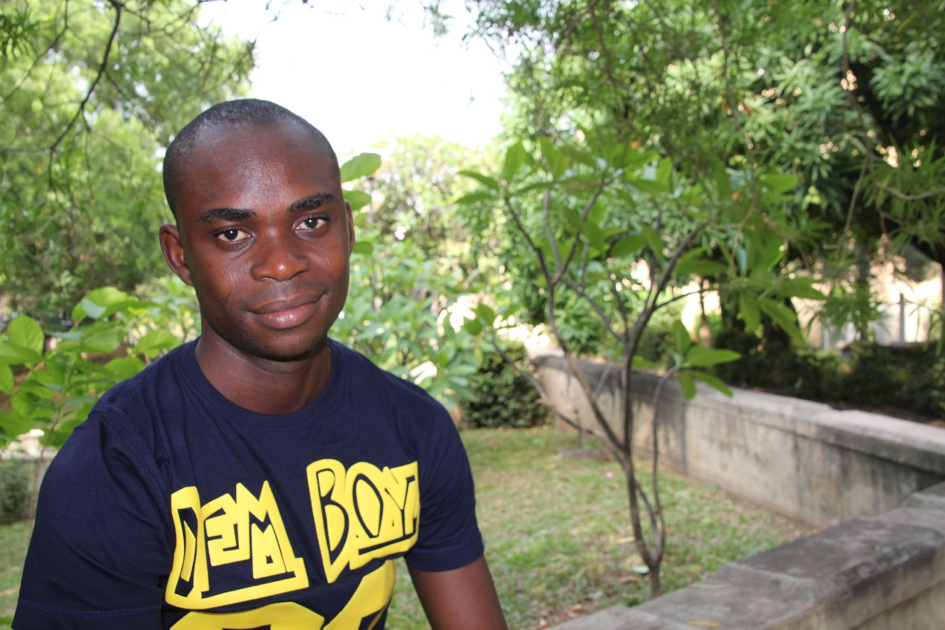

Our 2SCALE project helps farmers profit from their work by providing training and agribusiness linkages. Below is the story from a young farmer who chose the farm over the city.

My name is Yusuf Monimago from Kwara State, North Central Nigeria. I have a background in public administration at Kwara State Polytechnic, and I also trained for one year on commercial agriculture in Kwara State University.

During this training program, I developed the desire to go into a more modernized field of farming. There are a lot of machines, such as combine planters, pump sprayers, and combine harvesters, that can make a huge difference in Nigeria. But unfortunately, after graduating, I realized how hard my dream would be to achieve, and since we have no access to those machines, we now find agriculture very hard work.

Nonetheless, I decided to focus on agriculture because after interacting with other value chain actors involved in IFDC’s 2SCALE program, I now see agriculture as a lucrative business. As a graduated farmer, I use my own ideas to improve on my farming activities. I see the opportunity in improving my business to make a higher profit than I would working with the public sector under the government.

The difference between the salaries of a successful farmer, and a state government worker is huge. I’ll give you an example. If I plant 1 hectare of soybeans, I can produce 3 tons of soybeans, and 1 ton of soybeans is worth 115, 000 Naira (U.S. $407). I intend to plant about 10 hectares of land, and I should receive more than 3 million Naira ($10,628) in a year. However, if I am working under the government, the government pays me only 70,000-80,000 Naira ($248-$283), or 100,000 Naira ($354) at the very highest. Based on the cost stimulation exercises we conducted within the 2SCALE program, I can easily pay myself 100,000 Naira a month, unlike a young government worker.

My choice of doing agribusiness is not only based on money. I also aspire to contribute to feeding the people in Nigeria, specifically in Kwara State. That is why I am not limiting myself to 10 hectares of land. I still want more. When you are working for the government, they have something called a promotion. I want to promote myself. I want to increase from 10 hectares to 15 hectares, and from 15 hectares to 20 hectares. That is how I’ll promote myself.

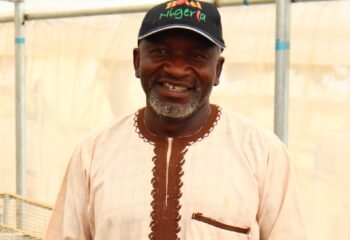

I had 2 hectares of land last year, and I intend to plant about 10 hectares this year. I made this decision after I discovered the International Fertilizer Development Center (IFDC) through a link from the Ministry of Agriculture, Kwara State chapter. Mr. Thompson Ogunsanmi, coordinator of 2SCALE programs in Nigeria, explained the 2SCALE program to young farmers in our association, as well as why IFDC is there, what the organization’s goals are, and how we can fully participate.

We started in 2011, and since that first year, 2SCALE has enabled us to achieve lots of success. After my graduation from the training center with the state government program, we had access to some expensive agricultural equipment and machines, which were difficult to procure when we first started out as farmers.

During this collaboration with 2SCALE, we are seeing new ideas, and we are interacting with other business people to get access to relevant technologies. This process broadens our horizon and encourages us to reinforce our own business.

For example, we used to get 800-1,000 kilograms per hectares of soybeans, but now because of our collaboration with 2SCALE, we can improve our technology for soybean production by introducing inoculum technology. We obtained approximately 3 tons last year. Through 2SCALE, IFDC also let us see that faming is a more lucrative business where more than 100 percent profit margin is possible. 2SCALE encourages us to see ourselves as the most integral part of the big money value chain, because the input of suppliers and processors all depend on us as farmers. So, we must get our business right. This mindset is radical, and it may be one of the most important goals 2SCALE has helped us achieve.

We have a lot of challenges with weeds. The 2SCALE training assisted us in best management of weed control. 2SCALE also helped us realize that we are experiencing a lot of post-harvest losses, and we took a training seminar to reduce these losses. We saw that it was possible to reduce losses by 90 percent by adopting best post-harvesting practices and technologies, such as combine harvesters. In the past, we were using local, labor-intensive methods to harvest. First, we harvested the beans, then we gathered the soybeans on the ground, and then we beat the soybeans using sticks to remove the seed from the chaff. With this process, we lost a lot of soybeans. When 2SCALE came, the project introduced a machine that could thresh the soybeans.

In the past, we struggled with quality. We supplied Ma&Co, a processing company that buys our soybeans. They would tell us that there were a lot of stones in our collecting bags, as well as sand. However, after completing the training and learning the more modern technique, we have had no further complaints. Our labor has been reduced, and the threshing machine has reduced our losses. It makes our soybeans very clean, and now it has enabled us to meet the needs of our target market.

2SCALE also helped us to diversify our market. For example, we were connected to another buyer named EMMAN OKONTA & CO., and this became a way to negotiate for a better price. Before, we were selling 1 ton of soybeans at 85,000 Naira ($301), and now we are selling 1 ton at 115,000 Naira ($407). Everything is different now, because our quality has improved, and the market entry gates have diversified.

2SCALE has already demonstrated to us that farming can be a lucrative business. Now, our major challenge is to access finance to modernize our equipment. But all the machines I’ve mentioned are above our purchasing power.

During the cluster capitalization workshop, one of the ideas was to network with some of the local machine manufacturers before buying a manual planter from the United States. The manual planter costs about 50,000 Naira ($177) when there is not a clash in currency. But if the machine is manufactured locally, it is even more effective and costs just 35,000 ($123) Naira, even if the currency clashes. If 2CALE can facilitate the training for these manufacturers to build a combine harvester machine, then our dream may come true quickly.

This will make our production cleaner than using the thresher, and it will allow for a reduction of labor. We don’t need to travel to Japan or to China, because this manufacturer can easily provide the solutions to our problems.

This transfer of technology will definitely make our work easier, faster, and more effective. And it will attract more unemployed youth to agriculture.