This week Feed the Future, the U.S. Government’s Global Hunger and Food Security Initiative, is celebrating 10 years of #CultivatingHope to #EndHunger. As a Feed the Future partner, we are joining the celebrations by highlighting successes accomplished together. Today we are focusing on our joint research on phosphate rock.

Current phosphatic fertilizers and fertilizer production processes are inefficient and result in poor use efficiency of phosphate rock, a finite essential resource. In 2010, IFDC estimated that phosphate rock reserves and resources, at current production rates, may last only 350 years. In addition to waste of P, large amounts of undesirable byproducts are generated during phosphatic fertilizer production, which poses a disposal problem. Addressing these issues of sustainability requires dramatic changes to production and application of PR. Therefore, IFDC with its partners, including Feed the Future, are researching solutions that make sense for smallholder farmers.

In the 1990s, IFDC began looking at direct application of locally available phosphate rock for crop production. This research included partial acidulation of phosphate rock (reducing the amount of acid needed to produce water-soluble phosphorus (WSP) fertilizers). Though the research yielded good agronomic results, the acidulation process proved costly due to issues of transport and handling of the acid.

Activated PR

Since then, IFDC scientists have been exploring innovative and practical approaches to enhancing the agronomic efficiency of directly applied phosphate rock (PR). It was found that compaction of ground PR with WSPs, such as triple superphosphate (TSP), could “activate” PR and make it suitable for direct application. This process should leapfrog the transportation costs and handling of acid encountered by partial acidulation and enable small mining companies to utilize indigenous PR mines previously unsuitable for commercial production.

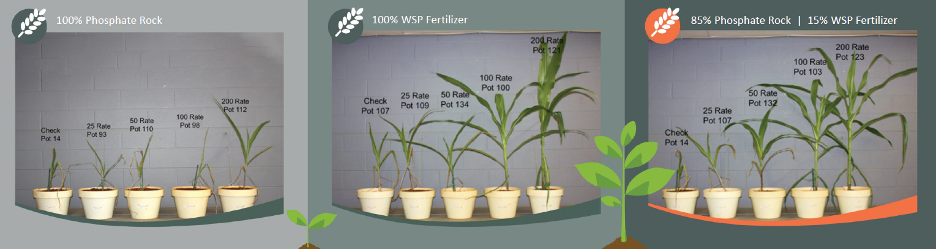

Using a 1:1 compaction ratio of TSP and PR, IFDC scientists discovered that the PR became more reactive and yielded a relative agronomic effectiveness (RAE) value greater than 80% in greenhouse trials. Though the research found that this compacted PR was just as effective as TSP, the process, with a 1:1 compaction ratio, was still heavily reliant on expensive WSPs.

As research progressed, it was found that the WSP:PR ratio could be reduced to make the process less expensive and more attractive to small-scale mining operations. Through the Feed the Future program of the U.S. Agency for International Development (USAID), IFDC began evaluating activated PR in greenhouse trials in 2014 using 20% diammonium phosphate (DAP) or monoammonium phosphate (MAP) with 80% PR. PRs of varying reactivity, from non-reactive to highly reactive, were evaluated on rice, maize, and soybean grown in three soils with varying acidity/alkalinity levels. Beginning in 2017, in collaboration with MINBOS, an Angolan fertilizer company, additional greenhouse trials were conducted using Angolan PR on maize, wheat, and sorghum.

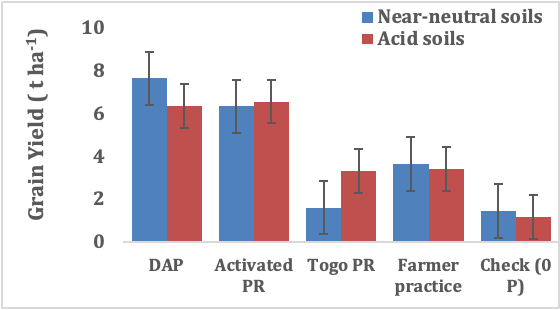

Preliminary results indicate that activated PR provides opportunities for direct application of low to medium reactivity PRs with realistic yields and on a wider range of soils. Field trials are in progress in Ghana and Kenya with additional trials planned for Angola and Niger.

More Efficient Activation

Expanding on our activated PR findings, laboratory and greenhouse research is being conducted to investigate alternative “activation” processes using bio-organic acids, biofertilizers, and bio-nanotechnology. This research will also provide opportunities to remediate heavy metals from phosphatic fertilizers.

While waiting for results from this research, it is hoped that new production methods will extend the life of current PR reserves and resources, as well as reduce environmental contamination through decreased biproducts.

Impacts and the Future of Phosphorus

Sitting in his basement, observing the glow of the newly discovered element, Hennig Brand had no idea that in 350 years, phosphorus would be responsible for keeping billions of people alive. If the predictions are right, we only have around that same amount of time until once-nourished soils, plants, and people will begin to suffer due to lack of PR reserves and resources. No matter how much PR reserves and resources are left in the earth, they must be manufactured and used more efficiently. Once gone, we are not going to get it back.

But there is hope. IFDC’s research on activated phosphorus through the Feed the Future Bureau of Resilience and Food Security-Soil Fertility Technology (RFS-SFT) project presents an opportunity to advance greater efficiency in phosphorus fertilizer production by finding a purpose for previously unusable byproducts. Additionally, the results shown from current research potentially unlock new horizons for governments to save on fertilizer import costs, for small mining companies to utilize previously untapped mines, and for smallholder farmers to access critical nutrients for their farms, enabling their families to better their livelihoods. In the research and development world, we call that a win-win-win. The research accomplished through meaningful partnerships will enrich, enhance, and extend the lives of millions for years to come.

This blog is made possible by the generous support of the American people through the United States Agency for International Development (USAID) under the Feed the Future initiative. The contents are the responsibility of IFDC and do not necessarily reflect the views of USAID or the United States Government.